TECHNOLOGY AND

SCIENTIFIC KNOWLEDGE:

SOLVING OUR PROBLEMS

UNIT DIRECTIONS: Read and study the following lesson carefully, and then answer the test questions that appear at the conclusion of the lesson.

Technology helps to produce the product that results from using scientific knowledge. The desire to know has always driven mankind to inquire and to hypothesize the reason why of an occurrence. Computer technology has allowed scientific information to advance at a greater rate than was physically possible prior to computers. Information in one area of science can be useful to scientists in other areas of research. Teflon, as an example, was developed by DuPont, and utilized by NASA, to protect the rocket capsule from excessive heat on re-entry into the earth’s atmosphere.

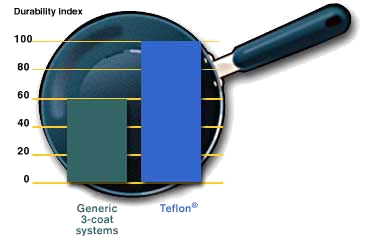

The exceptional performance of DuPont non-sticks is made

possible by the characteristics of their unique main ingredient, Teflon®

fluoropolymer resin.

DuPont invented non-stick surfaces for cookware and has been the leader ever

since. We hold the majority of all patents granted in non-stick technology. And

we're proud to say we're the undisputed leader in research and development,

quality assurance, non-stick performance, and consumer trust!

Unlike most other competitive non-sticks, DuPont branded non-sticks feature

patented multi-layer technologies to ensure superior performance and

durability:

A unique topcoat: for easy

food release and easy cleanup

A tough midcoat: for excellent resistance to scratches and

abrasions

A rugged primer: for long-lasting durability

DuPont certification seal means you can trust cookware to meet the toughest DuPont standards for quality and performance. Standards are upheld by a unique 13-point checklist for quality assurance. Plus, DuPont tests cookware in a rigorous battery of real-world tests, including over 30 years of in-home kitchen testing and an ongoing program of professional chef testing conducted in commercial restaurants.

Before a manufacturer is licensed to use a DuPont non-stick

coating, they must submit their products to DuPont to make certain that

exacting quality standards are met. Once a manufacturer is licensed, DuPont

conducts periodic testing to ensure that those standards are consistently

upheld. Finally, each manufacturer conducts in-house tests against their own

quality standards.

When you see the Teflon® logo or "seal," you are guaranteed to get

the quality, durability and performance you need for easier cooking and

cleanup.

Building a Better Heart

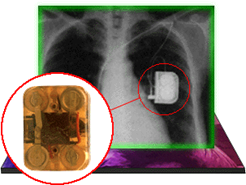

In some cases, heart disease may be so severe that the

patient may not survive the wait for a donor heart. Medical scientists have

developed electronic devices such as defibrillators, pacemakers, and artificial

heart models that can keep the patient alive until a heart becomes available.

One of the best known devices is the "Jarvik-7" artificial heart,

named for its designer Robert K. Jarvik, an American physician. Designed to

function like the natural heart, the Jarvik-7 has two pumps (like the

ventricles), each with a disk-shaped  mechanism that pushes

the blood from the inlet valve to the outlet valve.

mechanism that pushes

the blood from the inlet valve to the outlet valve.

The action of the artificial heart is entirely similar to the action of the natural heart. There is, however, one huge difference: the natural heart is living muscle, while the artificial heart is plastic, aluminum, and Dacron polyester. As a result, the artificial heart needs some external source of "life." An external power system energizes and regulates the pump through a system of compressed air hoses that enter the heart through the chest. Since the system is cumbersome and open to infection, the use of an artificial heart is meant to be temporary.

The Jarvik-7 was first used during the early-1980s. However, earlier artificial hearts date back to the mid-1950s. In 1957, a team of scientists, led by Willem Kolff, a Dutch-born physician, tested their model in animals to identify problems. In 1969, a team led by Denton Cooley of the Texas Heart Institute successfully kept a human patient alive for more than sixty hours with their model. During the years that followed, the notion of a permanent, rather than temporary, implantation began to take hold.

In 1982, a team led by William DeVries of the

Since then, development of an improved artificial heart has continued. One possibility is an electrical heart powered by a small wearable battery that does not require any break in the skin. Perhaps, someday, the artificial heart will become a realistic, permanent option for survival.

SUCCESS STORY: Nanoparticles used to develop better vaccines

SUCCESS STORY: Nanoparticles used to develop better vaccines

The Foundation for Research, Science and Technology is

investing $5.9 million over five years in research into carbohydrate

nanotechnology, being carried out by Industrial Research Limited (IRL), the

The program involves 17 researchers who are attempting to make tiny sphere scaffolds, measuring just nanometers across, which will be coated in sugars and used for vaccines.

The first vaccines were actually weakened or dead viruses or bacteria. These vaccines frequently cause mild illness and complications, so modern vaccines are made from purified proteins taken from the bacteria or virus. However these proteins are not considered a threat by the body and so the immune system does not respond to them.

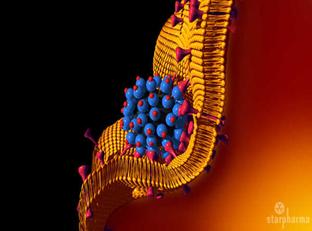

Project leader Dr Phillip Rendle, a chemist with IRL, says that if we want the body to respond to the vaccine proteins we must trick the body into thinking they are dangerous. Nanoparticles covered in the right sugars will look dangerous to the body and so force the immune system into action.

(above) A sugar

coated nanoparticle interacts with receptors on a cell membrane.

“The sugars involved can have

quite complex structures and can be very difficult to make synthetically.” One

possible source of the carbohydrates is from nature, such as

“These long chains will be broken up by chemical treatment or with enzymes to give useful structures for attachment to the nanoparticles.”

Two forms of nanoparticles are being explored. One uses a dendrimer skeleton, a highly branched structure provided by Starpharma. The other uses

nanoparticles commonly used in animal vaccines, but currently unsuitable for humans.

For additional information on

dendrimers click on the PDF File.

Non-energy benefits include comfort, a cleaner

environment and not having to shift house.

Technologies that save energy and make houses more comfortable, longer lasting and healthier are expected to result from a four-year research project underway in New Zealand.

The research, titled 'Towards the Zero Energy House' is being carried out by BRANZ Ltd, which is working with several universities and a consortium of private New Zealand and international companies. The Foundation for Research, Science and Technology is providing a total of $1.1 million for the four-year project.

Senior scientist and project manager, Albrecht Stoecklein, says the aim is to develop building standards that incorporate energy saving technologies, which are not merely about reducing the size of the next power bill.

The research is attempting to put a dollar value on the range of other energy saving features, known as non-energy benefits, such as comfort or health benefits achieved through double glazing and improved insulation.

"Energy technologies do much more than save energy," says Mr Stoecklein, who estimates non-energy benefits are often two or three times higher than energy savings.

"The tricky part is that these benefits are difficult to quantify with hard numbers," he says. "Occupiers may consider a house more comfortable but what's that worth? We're trying to quantify these less tangible benefits."

The aim is to improve living conditions and the thermal performance of New Zealand houses by developing guidelines for assessing the suitability of new energy-efficient technologies. Researchers hope the results will encourage home owners to change their mindset from merely gauging power bill savings to concentrating on better quality of living and environmental advantages.

Results will give the Government and other authorities an indicative dollar value on which to base future policies or education, and perhaps lead to building code changes, using cost benefit analysis that architects and others in the industry can apply.

Stoecklein says this is the first time New Zealand has undertaken such comprehensive research and he believes it is also the first time such research has been done outside the US. The final two years of the study include an analysis of benefits beyond the home. These include greater employment opportunities created through the manufacture and installation of technologies and power delivery cost savings.

Energy saving practices range from improved housing design where north facing windows are used to capture more heat from the sun, concrete floors that trap the daytime heat for release during cooler hours, insulation, double glazing, solar water heating, energy efficient heating and cooling or simply using a draft strip around doorways or blocking disused chimneys to prevent heat loss.

![]() Now answer questions 1-11.

Now answer questions 1-11.